Overview

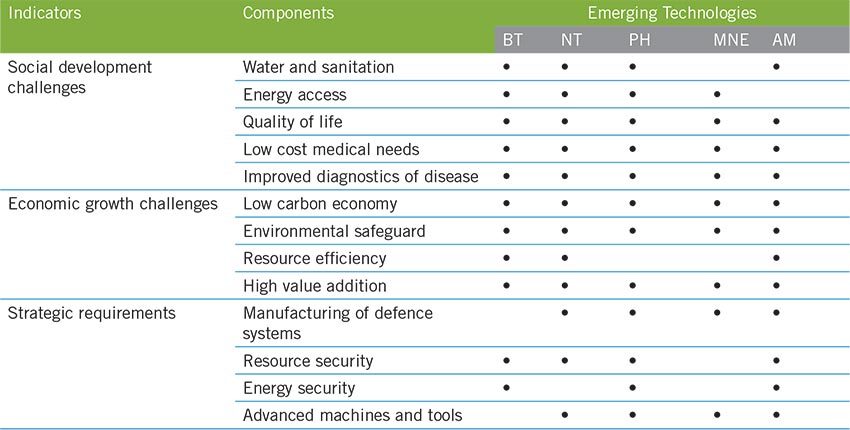

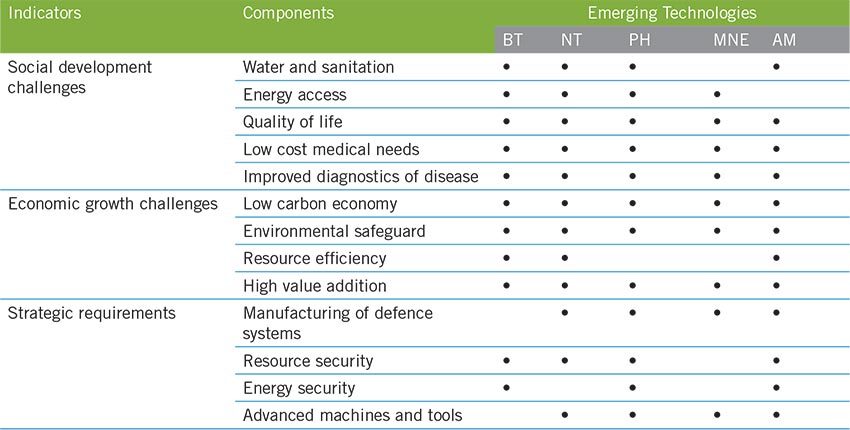

This study identifies five key technologies, having the maximum potential to stimulate growth in Indian manufacturing: biotechnology, nanotechnology, micro and nanoelectronics, photonics, and advanced materials. These five knowledge intensive technology areas have wide-ranging applications across various industrial sectors with the potential to meet national security priorities, stimulate economic growth as well as meet social development imperatives.

The study was released on the heels of the National Capital Goods Policy, during the Make in India Week in 2016, which includes a provision for a Technology Development Fund and other commitments such as increasing skill availability, ensuring mandatory standards and promoting growth and capacity building of Micro, Small and Medium Enterprises (MSMEs). The study identifies how to deploy this fund most effectively.

Key Findings

- A large share of the total manufacturing output (calculated in terms of Gross Value Addition) can be impacted by the identified technologies: biotechnology (15%), nanotechnology (86%), micro and nanoelectronics (100%), photonics (19%), and advanced materials (40%).

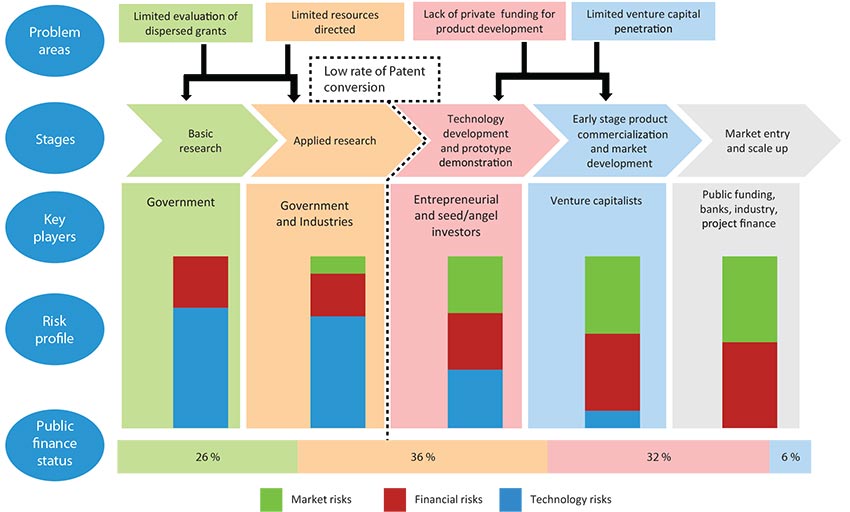

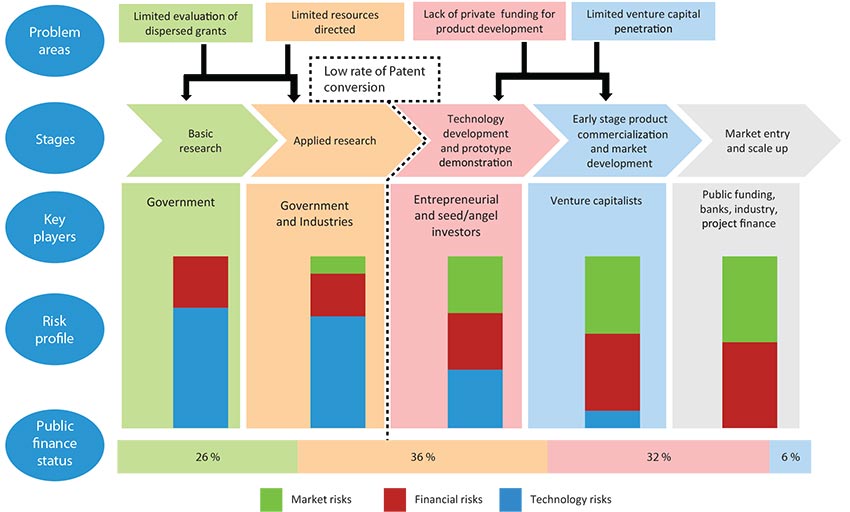

- The lack of participation of the private sector in R&D is one of the key hurdles preventing India from becoming an innovation hub.

- The private sector contributes less than one-third of the total expenditure on R&D.

- The inefficient and understaffed Indian Patents Office (IPO) is another key hurdle.

- In 2012 the IPO had 123,255 pending patent applications, which have further increased to 246,495 pending patent applications (in addition to the 532,682 pending trademark applications) in 2015.

- The quality and standards associated with domestically manufactured finished-goods and intermediates do not meet international, or even national standards.

- There is a need for an accreditation entity such as National Accreditation Board for Testing and Calibration Laboratories (NABL) to take up a pivotal role and certify the bulk of testing laboratories across the country. Currently, only one per cent of laboratories are accredited by NABL.

Enabling technologies potential to address challenges and requirements for India’s progress

Source: CEEW analysis, 2016

Key Recommendations

- The public sector must become a risk capital provider and move to a royalty-based system that allows for revenues to flow back to the public corpus.

- A centralised technology information portal that provides a range of information must be developed.

- Capacity expansion of the IPO (both funding and manpower) and outsourcing ‘prior-art’ searches to third party providers would improve the efficiency of the patent filing and approval process.

Technology development chain

The proportion of risks highlighted is only a quantitative representation of observations. (Source: CEEW analysis, 2016)

IPO staff in India experience the highest per capita workload (20 applications a month, as compared with seven in Europe and China, eight in the United States) at the lowest pay.