The Indian textile industry supports farm and non-farm livelihoods and is considered one of the critical sectors of India’s rural economy. However, factors such as erratic power supply, high power tariff, lack of raw materials and limited access to modern technology adversely impact rural workers’ livelihoods.

Approximately, 93 per cent of the reelers and weavers of the silk industry located in West Bengal’s Murshidabad district complained about the lack of raw materials and faced significant challenge in the production1.

Further, unequal power tariffs among different states in India have impacted the textile products’ competitiveness in the market. Power tariff in Surat was Rs 7.5 per unit, while the same in Maharashtra was Rs. 3.5 per unit. So, leaders from the textile sector in Gujarat’s Surat demanded a ‘one nation-one-power tariff’ policy to be implemented in the country2.

The Indian textile industry comprises varied hand-woven and hand-spun region-specific products and various mills, giving it national prominence as well as an advantage in global exports. Thus, the current predicament of the textile industry is a topic of frequent discussion among the related stakeholders.

The textile industry contributes around 2 per cent to the country’s Gross Domestic Product (GDP), with a total export share of 11.4 per cent in 2020-213.

Figure 1: Landscape of Indian Textile Industry

Climate change adversely impacts the growth and production of natural fibres required to prepare threads for the textile industry4. This has led to a shortage of raw materials and is affecting production numbers. The industry is also known for being one of the most polluting industries in the modern world, leaving a huge impact on the environment.

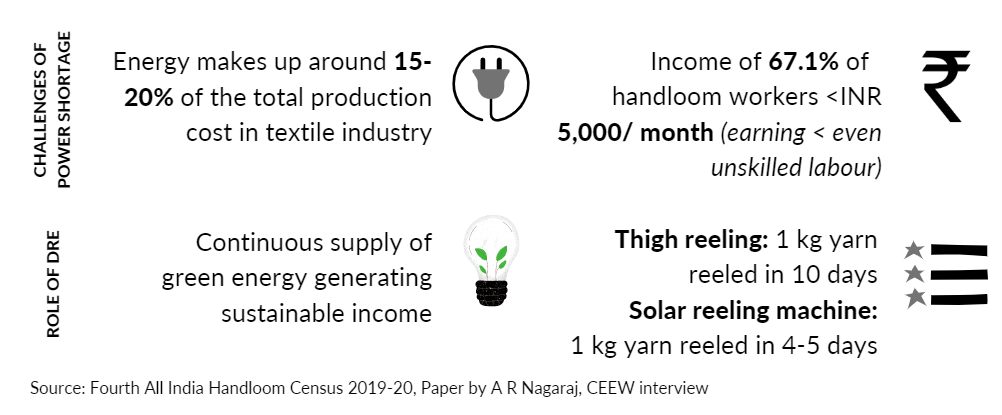

Though textile is one of the mainstay industries for the nation’s economy, it faces acute power shortages. Erratic power supplies affect production and increase production costs. The use of energy alone makes up around 15-20 per cent of the total production cost5.

Thus, any increase in tariffs impacts artisans’ livelihoods. Around 67.1 per cent of India’s handloom workers earn less than INR 5,000 per month (Figure 2).

Figure 2: Role of DRE in the Textile Industry

This means that weavers in the sector earn less than even unskilled labourers (the minimum wage for unskilled labour in agriculture was in the range of INR 372-INR 411 per day)6. Therefore, it could be concluded that the industry is heavily dependent on electric equipment that relies on quality energy supply for efficient functioning.

India also continues to rely heavily on conventional sources of energy. Given that the textile industry is one of the highest energy consuming industries in India, the carbon footprint of each apparel continues to increase. It thus questions the sustainability parameters of the industry.

Decentralised Renewable Energy (DRE) can significantly accelerate the scale of textile production. It could also improve the productivity and incomes for rural micro-, small- and medium-scale enterprises.

In a CEEW survey with the end-users of Reshamsutra (a solar silk reeling machines producing enterprise) in 2022, a little more than 94 per cent respondents experienced an increase in income. The end-users also noted that the machines improved the quantity of yarn produced daily. For instance, earlier, one kilogram yarn was reeled in 10 days from thigh reeling, while from a solar reeling machine, it was completed in 4-5 days (Figure 2).

However, the major challenges observed during the survey was the lack of access to raw materials and the output quality. Of the total respondents who were not using the product currently, 31 per cent stated that they discontinued due to the lack of raw material availability. A significant question which needs to be addressed is whether green energy is sufficient for the industry to flourish and to make workers in rural areas self-sufficient.

Figure 3: Market Linkages of Handloom Workers

Given the challenges the textile industry faces, the erratic power supply is a significant concern as it impacts the livelihood of rural artisans and workers. It could be one of the key determinants behind the 19 per cent decrease in the overall number of weavers from 43.31 lakh in 2009-10 to 35.25 lakh in 2019-20. Considering this, the Indian government has released a framework for DRE livelihood applications7. The policy framework states that DRE-based livelihood solutions have the potential to reduce the dependence of rural livelihood on diesel.

However, to increase the adoption of DRE-based livelihood products in the industry, access to affordable and customised financing, steady technological innovation and updated vocational training centres are required. Furthermore, close coordination between stakeholders across sectors is essential to build an ecosystem for DRE solutions for workers. In addition to energy supply, it is also expected to address challenges related to the paucity of raw materials, lack of awareness regarding government schemes and training facilities, obsolete machinery, market linkages, and end-user financing.

The textile industry holds importance because of its contribution to the economy, employment generation and fulfilling people’s most basic needs. Overcoming the current issues is vital to strengthen the industry’s performance and improve the sustainability of textile production.

Notes

1 http://ndpublisher.in/admin/issues/IJSSv6n3e.pdf

3 https://www.investindia.gov.in/sector/textiles-apparel

4 https://oecotextiles.blog/2019/02/26/textile-industry-and-climate-change/

5 https://textilevaluechain.in/news-insights/renewable-energy-weaved-into-indias-textile-industry//

6 https://pib.gov.in/PressReleasePage.aspx?PRID=1720676/

7 https://mnre.gov.in/img/documents/uploads/file_f-1644909209115.pdf

Mousumi Kabiraj is a Research Analyst at the Council on Energy, Environment and Water (CEEW), an independent not-for-profit policy research institution. Send your comments to [email protected]

Add new comment