Suggested Citation: Gupta, Vaibhav, Tirtha Biswas, Karthik Ganesan. 2016. Critical Non-Fuel Mineral Resources for India’s Manufacturing Sector: A Vision for 2030. New Delhi: Council on Energy, Environment and Water.

Overview

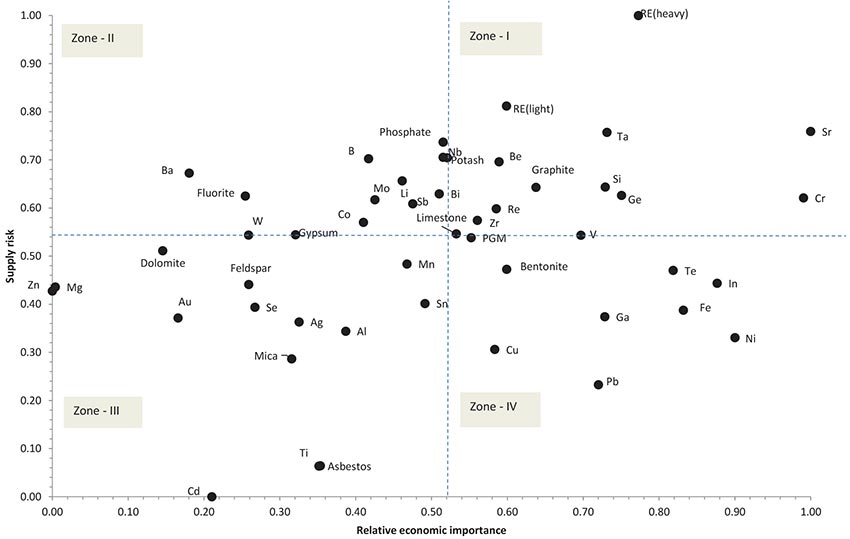

This study, supported by the Department of Science and Technology, Government of India, provides a first-of-its-kind framework for India to assess the impact of critical minerals on the manufacturing sector, considering both economic importance and associated supply risks. It identifies twelve critical minerals that could play an important role in the success of Indian manufacturing and the sustainable growth of the Indian economy.

The critical minerals including beryllium, germanium, rare earths (heavy and light), rhenium, tantalum, etc. find specialised use in a range of industries and modern applications, such as aerospace, automobiles, cameras, defense, entertainment systems, laptops, medical imaging, nuclear energy, and smartphones. These critical minerals would also play a role in nurturing the domestic manufacturing capacity to support the government’s low-carbon plans, such as the 100GW solar target, faster adoption and manufacturing of hybrid and electric vehicles, and the National Domestic Efficient Lighting programme.

Securing the supply to critical minerals, to satisfy exponential demand for consumer products, civil engineering, transport and energy infrastructure among others in a sustainable fashion, has become a major challenge for many resource dependent countries. Over the coming years, India will need to strategically develop joint partnerships with existing global players (private firms and governments) to secure assured supply of critical minerals.

India is 100% import dependent on heavy rare earth minerals, which find applications in the defence industry, and green technologies like wind turbines and hybrid vehicles, among others. (Source: Wikimedia Commons)

Snapshot of Critical Minerals for the Year 2030

Source: CEEW analysis, 2016

India has no declared domestic reserves for the majority of the 12 critical minerals, and is 100 per cent import dependent for seven of them.