Suggested Citation: Kumar, Sonal, Aditya Garg, Shikha Bhasin, Jitendra Bhambure and Torgrim Asphjell. 2023. Activating Circular Economy for Sustainable Cooling: How can India Effectively Manage the Lifecycle of Refrigerants? New Delhi: Council on Energy, Environment and Water.

This study examines the multifaceted challenges and promising opportunities surrounding lifecycle refrigerant management (LRM) in India. It explores the imperative transition towards a circular economy approach while analysing the environmental impact of refrigerant emissions. Furthermore, it proposes a range of overarching policies, sector-specific measures, and financing options to facilitate the operationalisation of LRM in India.

India is witnessing a rapid surge in cooling demand that is set to increase eightfold in the coming decades. However, this remarkable growth is accompanied by a daunting challenge — the heavy reliance on refrigerant gases having high global warming potential (GWP). This will lead to an alarming amount of high GWP refrigerant gases accumulating in the cooling devices. Given the limited adoption of good servicing practices, unorganised waste management, and the lack of any policy directive for refrigerant management, the gases gradually get emitted into the environment during operation and at the end-of-life (EOL) of the cooling systems.

India’s commitment to phasing out hydrochlorofluorocarbons (HCFC) and initiating the phase-down of high global warming potential (GWP) hydrofluorocarbons (HFC) aligns well with the targets set under the Montreal Protocol and its Kigali Amendment. However, according to the India Cooling Action Plan(ICAP), the demand for cooling in India is set to rise eight-fold in the next two decades. This will result in the significant accumulation of ozone-depleting and high GWP gases in refrigerant banks at the end-of-life (EOL) of cooling devices (MoEFCC 2019). Furthermore, gas leakages during the operational lives of these devices, which account for approximately 40 per cent of annual refrigerant consumption, pose significant environmental challenges (MoEFCC 2019).

To prevent the emission of these potent refrigerant gases and accelerate progress toward phase-down targets, a comprehensive lifecycle refrigerant management (LRM) plan is essential. Such a plan should focus on minimising leakages; promoting recovery, recycling, and reclamation for reuse; as well as ensuring the proper destruction of gases at EOL. By implementing LRM practices, India can mitigate the adverse environmental impacts that can be caused by refrigerant gas emissions.

This report aims to provide recommendations for operationalising LRM in India and answers the following research questions:

To address these research questions, we conducted extensive desk research, collecting information on the current status, policies, regulations, challenges, and issues related to refrigerant management in India. Furthermore, we undertook a literature review of global best practices and a study trip to Norway to gain insights and learn from successful policy initiatives, implementation mechanisms, and practices in refrigerant management.

In addition to desk research, we held focused interviews and discussions with experts and stakeholders from the refrigeration and air-conditioning industry. These engagements were aimed at gathering valuable insights and perspectives on existing challenges as well as potential policy initiatives, implementation mechanisms, infrastructure requirements, and other support needed for the effective implementation of lifecycle refrigerant management in India.

The leakage of refrigerants into the atmosphere happens at every lifecycle stage of a cooling product. Leakages could occur due to improper installation or due to leaks in the cooling circuit that have developed over time due to exposure to corrosive environmental conditions. Sometimes, the refrigerant gases are also vented off during servicing or EOL. LRM aims to avoid any release of refrigerant gases into the atmosphere either through leakages or intentional venting. Thus, LRM must focus on the following:

Globally, several countries have undertaken refrigerant management initiatives. These initiatives include regulations, policy mandates, incentive schemes, or a combination of these, and they differ in their approach and scope. While some countries have established strong regulations with robust procedures for monitoring and enforcement (e.g., Japan), others have initiatives based on incentivising the stakeholders in the EOL management value chain (e.g., Norway, Denmark, US, Japan). The refrigerant management programmes also vary in scope – while some countries focus on reclamation and reuse, others focus on the destruction of gases after recovery.

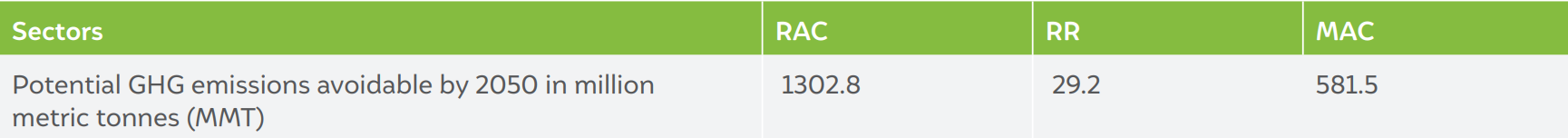

ES Table 1 Sector-wise cumulative greenhouse gas emissions avoidable by 2050 through LRM

Source: Authors' analysis

Drawing from global best practices and factors that have contributed to the effective management of refrigerants in other countries, we have identified the following mechanisms, which are relevant for India:

Successful implementation of LRM practices in the residential air-conditioning (RAC), residential refrigeration (RR), and mobile air conditioning (MAC) sectors could help mitigate approximately 1.91 billion tons of cumulative CO2 eq. emissions by 2050. The sectorwise mitigation potential is presented in ES Table above.

Operationalising LRM in India has the following barriers and challenges:

One of the key barriers in LRM is the absence of a clear policy directive. The current policies and regulations related to India’s commitments under the Montreal Protocol and its Kigali Amendment focus on the phase-down or phase-out of targeted refrigerant gases. These do not provide any direction regarding LRM practices. Without any policy directive, it is difficult to channel support for essential measures needed for refrigerant management, such as skill development, establishing infrastructure and mobilising investments, and the development of standards.

In addition, there is a need for coherence and synergies between related policies. For example, according to the E-Waste (Management) Rules 2016, EOL air-conditioners and refrigerators must be recycled. Still, it does not provide any mandate for the recovery and safe processing of refrigerants in these devices. Coherence between policies and rules relating to refrigerant management, e-waste management, and vehicle scrappage will help integrate refrigerant management practices with existing waste management practices and infrastructure in the automobile and home appliances sectors.

For effective refrigerant management and to ensure the quality of the processes involved, various standards and guidelines are required for tools, equipment, and processes, such as standards for recovery machines, reclamation tools and processes, storage, and branding and handling of reclaimed gas cylinders. Standards from the Air-Conditioning, Heating, and Refrigeration Institute (AHRI) and the International Organization for Standardization (ISO) are available globally for many of these tools and processes, but these need to be modified for Indian conditions and must be adopted. In addition, as some refrigerant gases are flammable and toxic, there is a need for guidelines and standard operating procedures (SOP) to ensure safety at the workplace.

As per the estimates in the ICAP, the demand for servicing technicians is expected to grow from 200,000 in 2017 to 20,000,000 by 2037 (MoEFCC 2019). A massive shortage of skilled and certified technicians for the proper installation, servicing, and maintenance of cooling devices is forecasted. In addition, refrigerant management practices will involve skill sets not covered in existing skill development programmes, such as the skills involved in performing recovery, recycling, and reclamation processes.

Without any policy directive or refrigerant management practices, the reverse supply chain and infrastructure required for refrigerant management(such as reclamation and destruction facilities, refrigerant collection, and testing centres) and the scale at which this is needed do not exist in India.

There is a need to increase awareness among end users about the adverse impacts of refrigerant leakages on the environment and the efficiencies of cooling products. Increased awareness of the benefits of good installation and servicing practices, and the options available for refrigerant management and proper waste product recycling and disposal, is essential in ensuring pro-active participation by end users in refrigerant management.

The Technology and Economic Assessment Panel(TEAP) provides a list of destruction technologies and their destruction efficiency, which can guide the establishment of effective infrastructure. This information can be used to set up and enhance facilities with high destruction efficiency, ensuring the optimal disposal of refrigerants and contributing to sustainable waste management practices. Destruction of refrigerant gases in cement kilns is one of the measures recommended by TEAP. Given the availability of several cement kilns in India, establishing proper linkages between these facilities and ensuring their efficiency can help address limitations in refrigerant management. Through effective collaboration between relevant stakeholders, and by leveraging the insights from TEAP, the industry can overcome barriers and improve the overall refrigerant management system. Research and development are also needed to make improvements in the design and manufacturing of cooling products, for example, to reduce corrosion or enable the early detection of leakages using the Internet of Things (IoT).

A multi-pronged approach is recommended for the effective operationalisation of LRM in India (ES Figure 1). The following recommendations result from the inputs received from stakeholder consultations, the literature review, and the learnings from global best practices.

ES Figure 1 A multi-pronged approach is needed for operationalising LRM in India

Source: Authors' analysis

Regulatory measures

There should be a clear and firm policy directive for LRM. In addition, amendments to the Ozone Depleting Substances (Regulation and Control) Rules 2000, E-Waste (Management) Rules 2022, and Vehicle Scrappage Policy 2021 will be required to include provisions that areneeded to operationalise LRM in India.

Developing standards and guidelines

Establishing rigorous standards for the tools, equipment, and processes involved in LRM would be essential for maintaining the quality of these tools and their performance. In particular, there is a need for:

Training and certification of the workforce

Existing training or skill development programmes for technicians in the air-conditioning and refrigeration sectors mostly focus on installing, servicing, and repairing equipment. Under the HCFC Phase-out Management Plan (HPMP), efforts have been made to train a few thousand technicians across the country on good servicing practices (GSP) (MoEFCC 2017). The curriculums of these training programmes include some elements of LRM. However, to have a larger impact on controlling refrigerant emissions, these curriculums need to be modified to cover all the processes of LRM. In addition, these LRM elements must also be included in courses under the National Skill Development Mission (NSDM). The objectives of this proposed training initiative and certification are to:

Creating a supportive ecosystem for LRM

In addition to policy and regulatory measures, substantial efforts would be required to establish infrastructures and reverse supply chains for refrigerant management. Initiatives should aim to:

Reuse of recovered refrigerant blends after recycling and reclamation is generally avoided and not recommended by original equipment manufacturers (OEMs) due to overall efficiency concerns in India. However, this is a prevalent practice in developed countries such as the US. The US Environmental Protection Agency (EPA) standards or any other recognised standards on reclaiming and reusing refrigerant blends could be adopted as an initial step.

Awareness generation and nudging end user behaviour

Consumers should be educated on the harmful impacts of refrigerant emissions and encouraged to participate in refrigerant management. This could be by adopting good installation and servicing practices or proactively handing the discarded cooling products or vehicles to an authorised waste recycler.

Finance for LRM

Finance and investment will be one of the key pillars in operationalising LRM in India. Finance will be required on many fronts; however, in particular, access to finance must be ensured for:

Enabling Circular Economy in Used Water Management in India

Toolkit for "Preparing City Action Plans for Reuse of Treated Used Water"

Activating Circular Economy for Sustainable Cooling

Activating Circular Economy for Sustainable Cooling

Activating Circular Economy for Sustainable Cooling