Suggested Citation: Bakshi, Tuli, Hemant Mallya, and Deepak Yadav. 2023. Assessing India’s CO₂ Storage Potential: A Critical Analysis of What Lies Beyond the Theoretical Potential. New Delhi: Council on Energy, Environment and Water.

This study estimates the theoretical CO₂ sequestration potential in different geological formations in India, considering above-ground constraints such as no-go zones and population density. It provides policy recommendations to accelerate the exploration and development of such formations to imminently start Carbon capture and storage (CCS) projects in the country.

India emitted 2.95 gigatonnes (Gt) of CO₂ in 2018, which is expected to rise with continued growth. CCS is vital for India, since renewable power and clean fuel transitions alone cannot lead to net-zero emissions. CCS technologies allow any residual CO₂ emissions to be captured and permanently stored in underground reservoirs. However, India is still in the nascent stages of CCS development, with few studies evaluating suitable CO₂ reservoirs and their storage potentials. Therefore, it is essential to hasten research and development of CO₂ sequestration sites to support India’s 2070 net-zero goal.

Carbon capture and storage (CCS) is vital for India to be self-reliant, achieve net-zero GHG emissions by 2070, and ensure a just transition. Despite India promoting renewable and alternative energy sources, long-term projections show that to meet the growing energy demand of power systems and industries, fossil fuels will need to remain an integral part of India’s energy economy (Malyan and Chaturvedi 2021). Cumulatively, India will have to inject 5.3–10 gigatonnes (Gt) of CO2 by 2050 to mitigate fossil fuel use–based emissions under 1.5°C temperature increase scenarios (Gambhir et al. 2022; Vishal, Chandra, Singh, and Verma 2021; Garg et al. 2017; Singh, Sharma, and Dunn 2021). Essentially, CCS can reduce emissions from key sectors of the economy without changing the existing fuel or technology mix. It could also help reduce the cost of the energy transition significantly, and, to an extent, avoid stranded assets in India in the future.

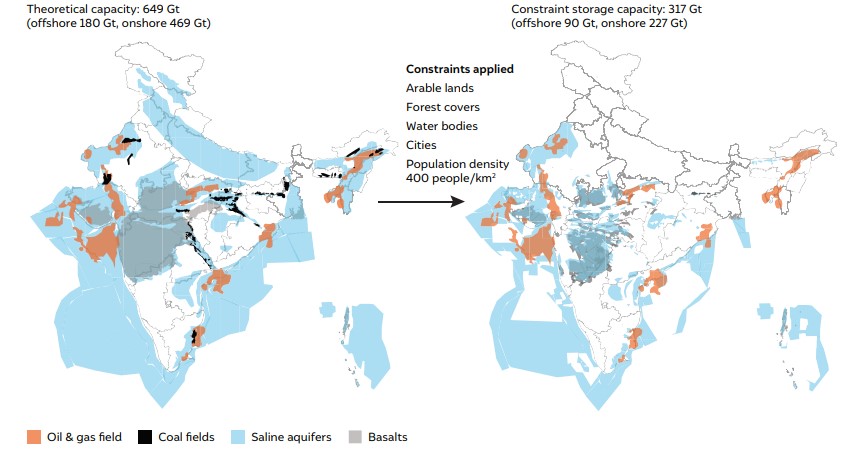

Geologically, CO2 can be sequestered in oil and gas reservoirs, unmineable coal beds, deep saline formations, and basalts. The theoretical storage potential of these reserves is 649 Gt (Figure ES 1). Of this, 326 Gt can be stored in deep saline formations and 316 Gt in basalts, while oil fields and coal formations account for 2.6 Gt and 4 Gt, respectively (Figure ES 1). Prior studies suggest that the vast majority of storage potential exists in the sedimentary formations of deep saline aquifers (Singh, Sharma and Dunn 2021). However, few studies have been conducted on basalts, which can be found extensively in the western part of India. Unlike sedimentary formations, basalts are harder due to different origins and chemical assemblage. Basalts act as the basement for other formations in much of the country. In sedimentary rock formations (such as saline aquifers), CO2 is trapped in pore spaces, whereas basalt can convert the CO2 into stone through mineralisation. India could be a global CCS champion, having, potentially, one of the most significant onshore basalt formations, globally. However, there is currently only one active basalt CCS pilot project globally, which is located in Iceland, where basalt has been used successfully to store CO2 due to suitable properties. Every basalt is different; therefore, we need to urgently assess India’s basalt formations to evaluate whether these are favourable for CCS.

If Indian basalts have suitable properties, developing a pilot CSS programme has dual critical benefits.

This is not to say that saline aquifers are not a promising option. However, from an overall risk–return trade-off perspective, and the fact that exploitation of both saline aquifers and basalt may take the same time and effort, basalt is an option that should not remain unexplored. Through our research, we provide a comprehensive analysis of various CCS options in India, highlighting the measures to be taken and the timeline to unlock these options.

Figure ES 1: Above-ground challenges could significantly reduce the area available for CO2 storage

Source: Authors’ analysis

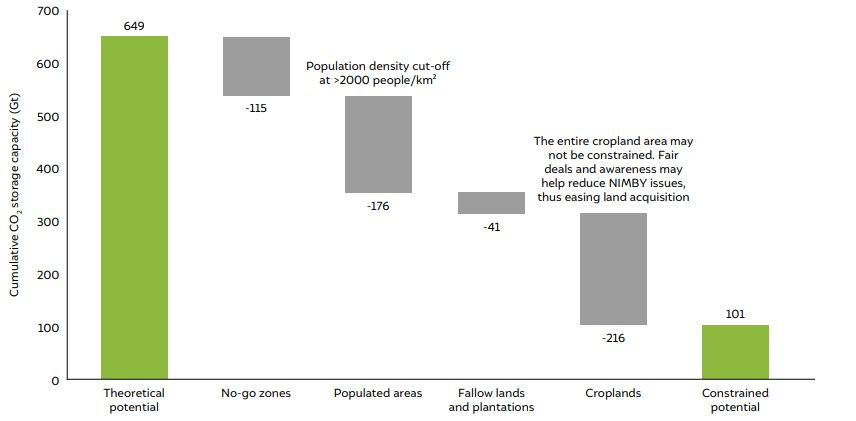

Figure ES 2: The theoretical CO2 storage potential is constrained due to the presence of no-go zones, human settlements, and croplands

Source: Authors’ analysis

CO2 storage sites exist deep under the Earth’s surface. But above them lie arable lands, forests, water bodies, no-go zones, and areas with high population density. These environmental, social, and ‘not in my backyard’ (NIMBY) factors are termed ‘above-ground challenges’, which limit operations and significantly reduce the areal extent of storage in India (Figures ES1 and ES2).

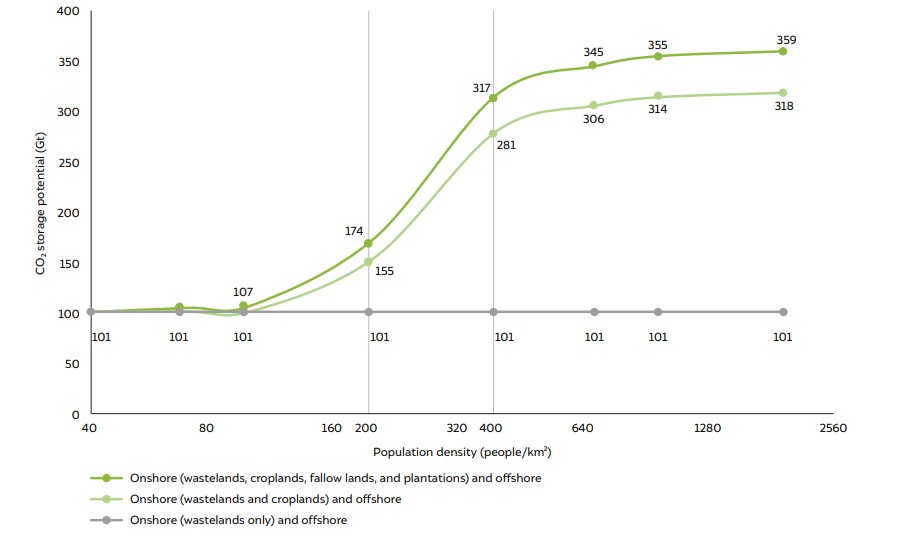

Per our analysis, the realisable storage potential tends to be a function of arable lands and population density, as depicted in Figure ES3. This constrained storage potential ranges between 359–101 Gt. The gap between realisable storage and the theoretical potential can be attributed to the challenges mentioned above (Figure ES 2). Additionally,

Figure ES 3: The constrained storage potential is a function of the population density and land use

Source: Authors’ analysis

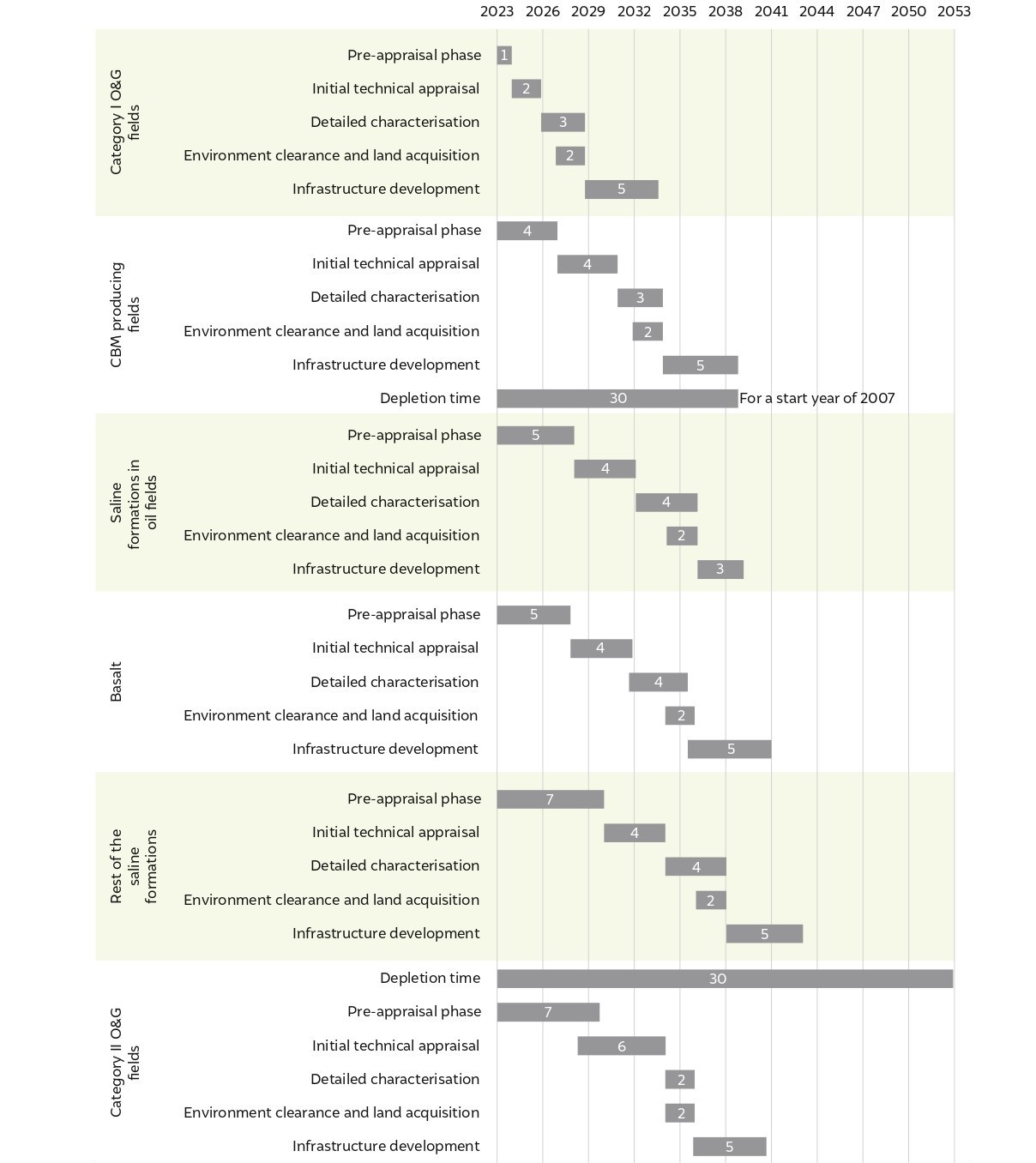

Figure ES4 presents the probable timeline for beginning commercial injection in various reservoir types. India can start with large scale CO2-enhanced oil recovery (EOR) within ten years. However, injection in other kinds of reservoirs is crucial, since oil and gas fields alone will not be able to meet India’s CCS needs to achieve net-zero emissions. Further, the figure demonstrates that the work that needs to be undertaken in the next five years is crucial to ensure that India builds sufficient CCS capacity to meet its net-zero target.

Dedicated research and data generation are needed to explore potential CO2 storage sites in saline formations and basalts. Technical feasibility studies and other research/data generation on CCS in oil and gas fields and active coal bed methane (CBM) fields might take less time since data already exists for both these resources. However, of India’s entire reserves, oil and gas reservoirs contribute to only 2 per cent, while the remaining is contributed by saline formations and basalts combined. Despite this skewed distribution, injection in oil and gas fields is being prioritised for cost recovery through EOR. The first CO2-EOR project in the depleted Gandhar fields in Gujarat is expected to start injection soon (Business Wire 2022).

Saline formation and basalt formations are entirely unexplored from the perspective of CCS. Injection could take up to two decades to begin for these wholly untapped, unexplored, and promising reservoirs unless rigorous research starts at the earliest. To unlock this significant CCS potential, data generation over the next five years is critical. This will set India as a forerunner of CCS in South Asia and unlock monetisation opportunities.

Figure ES 4: Timeline depicting initiation of probable commercial injection

Source: Authors’ analysis

CCS technology allows the carbon dioxide (CO₂) in industrial exhaust gases to be captured, transported, and permanently stored underground. CCS technology will support India in achieving its net-zero goal by capturing residual CO₂ emissions from hard-to-abate industries that can otherwise not be mitigated through energy efficiency measures or clean energy transitions.

Carbon capture is the process of removing CO₂ from industrial exhaust gases by utilising gas separation systems. Carbon storage is the process of injecting the captured CO₂ into underground rock formations for permanent storage.

Captured CO₂ is stored by injecting it into underground geological formations like basalts, saline aquifers and depleted oil and gas reservoirs. These formations need to have suitable characteristics to safely store CO₂ permanently.

The main risk associated with carbon capture is the risk of leakage of the captured CO₂. Such leakage can be a safety issue in the case of a significant breach in a formation and could potentially have damaging effects on the environment. Leakages will reduce the effectiveness of CCS technologies in decarbonisation.

CO₂ injected into basalt formation mineralises and forms mineral carbonates that are solid in nature. Hence, the gaseous CO₂ is chemically transformed and does not pose the risk of leakage. Mineralisation may take 5 - 10 years or even less depending on formation characteristics.

Assessing Effectiveness of India’s Industrial Emission Monitoring Systems

Evaluating Net-zero for the Indian Cement Industry

Evaluating Net-zero for the Indian Steel Industry

Accelerating the Implementation of India's National Green Hydrogen Mission

Best Practices in CEM (Continuous Emission Monitoring)