Suggested Citation: CEEW. 2023. Addressing Technology Gaps through Collaboration on Advanced Cell Chemistry Batteries. New Delhi: Council on Energy, Environment and Water

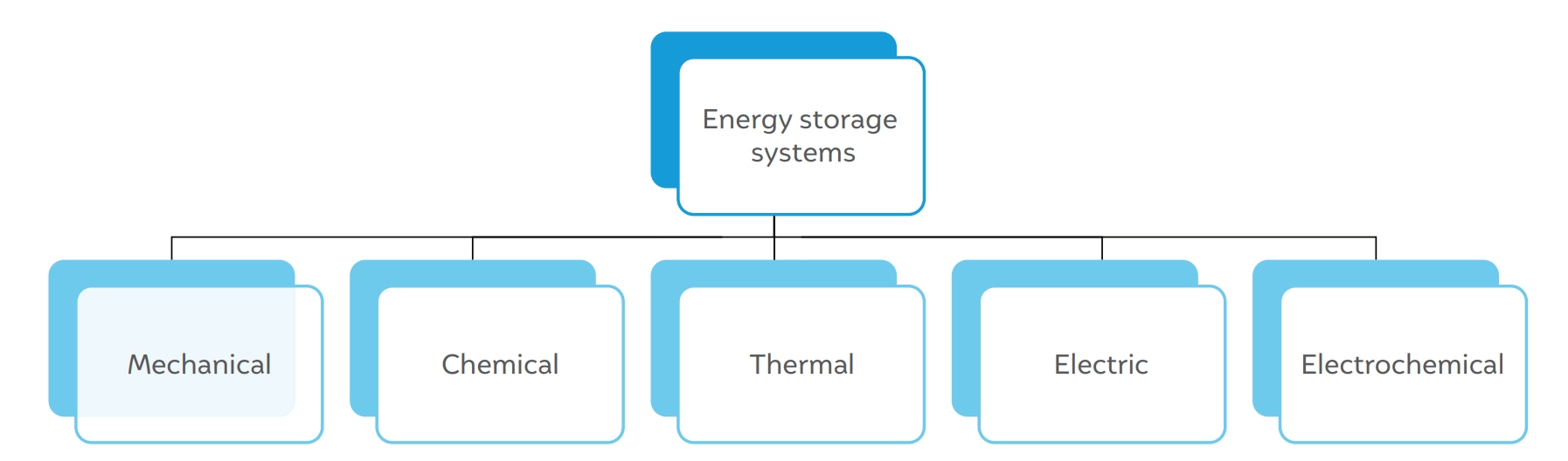

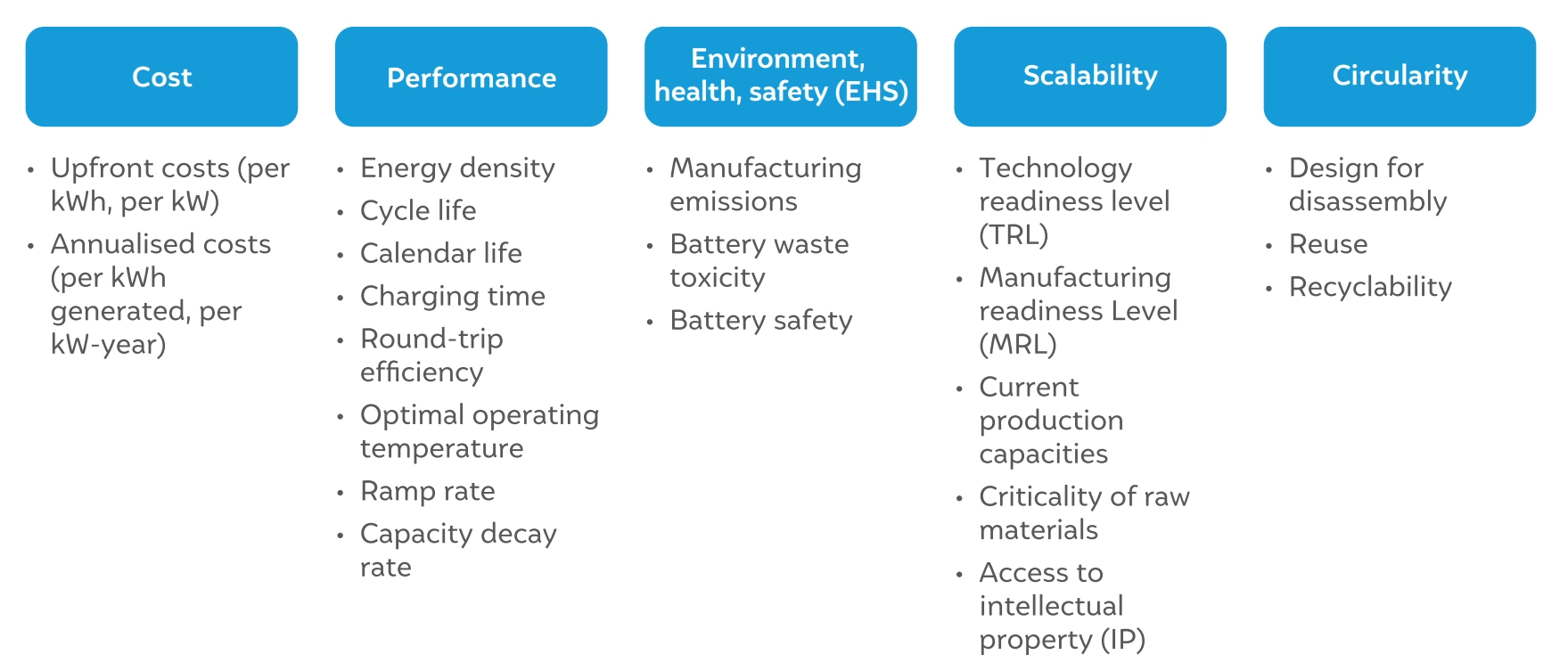

This report highlights the most significant technological gaps across five indicators and developed associated metrics to assess and track the progress of advanced cell chemistry (ACC) batteries, such as battery cost, its performance, environmental, health and safety impacts of battery technologies, scalability and circularity. It also examines several innovations in processes across the battery value chain which enable the development of new ACC batteries. Energy storage technologies are set to play a crucial role in reducing carbon emissions across the power and transportation sectors. While there exist various energy storage methods such as mechanical, chemical, thermal, electric, and electrochemical technologies, particularly batteries, have garnered significant attention from industry and consumers due to their adaptability and versatility in deployment.

The Group of Twenty (G20) nations have been at the forefront of climate action, collectively representing a substantial share of the global renewable energy (RE) capacity and battery electric vehicle (BEV) stock. The study thus recommends specific action points for the G20 countries to address the vulnerabilities in the ACC battery supply chain by promoting innovation and co-developing technologies by leveraging the benefits of collective effort. It also emphasises the need to develop markets and unlock new avenues of deployment by sharing best practices and increasing the flow of finance.

Energy storage technologies will play a critical role in the decarbonisation of the power and transportation sectors. The Group of Twenty (G20) countries have led such climate action, representing a cumulative share of 86 and 89 per cent of global renewable energy (RE) capacity and battery electric vehicle (BEV) stock, respectively, in 2020. Although there are various types of energy storage technologies, like mechanical, chemical, thermal, electric, and electrochemical (Figure ES1), electrochemical technologies (batteries) have attracted particular attention from industry and consumers alike due to their modularity and deployment versatility. Electrochemical batteries are further classified as lead-acid, nickel-cadmium, lithium-ion-based, sodium-ion-based, redox flow, solid-state, and metal-air. Many of these batteries are classified as advanced cell chemistry (ACC) batteries.

The traditional batteries have found use in power and transport sector but numerous other applications, such as the electrification of aircraft, ships, and spacecrafts, can be unlocked by improving the technological gaps of the available batteries, including performance and safety. On advancements, even existing applications can potentially witness further scale up. Performance gaps are inextricably linked to the context that batteries are expected to perform in. For example, a high gravimetric energy density may be desirable for batteries used in mobile applications while a high cycle life may be required for energy applications using stationary storage. Safety gaps are linked to the inability of batteries to manage temperature fluctuations or internal heat dissipation, which lead to battery failures and fires. Such accidents also have direct implications for the safety of humans.

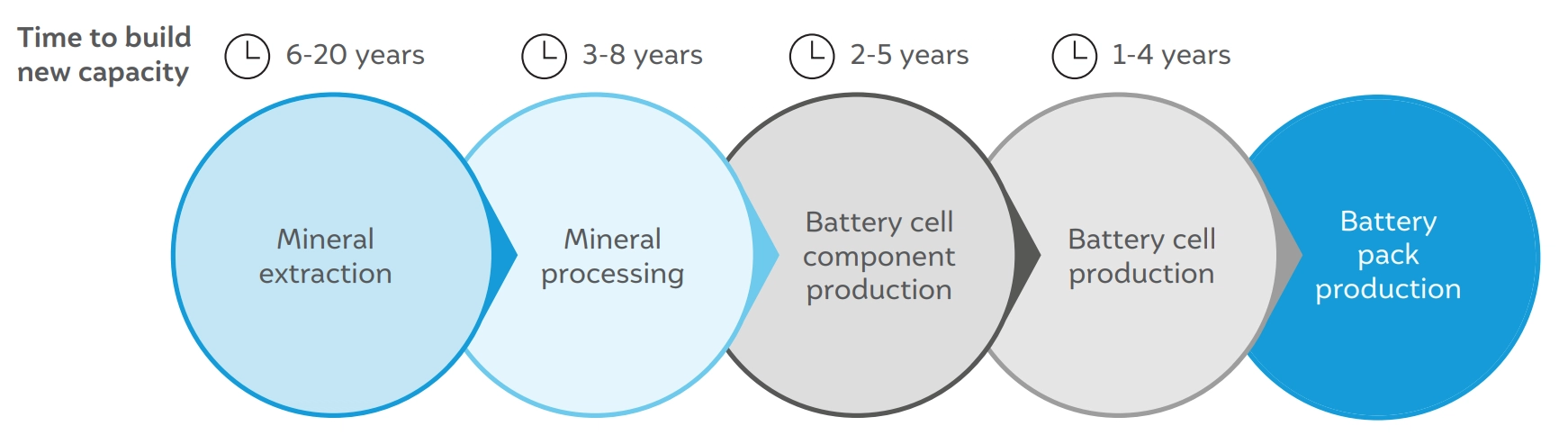

Beyond these technological considerations, the current generation of batteries is also plagued with supply chain and raw material gaps. Battery manufacturing is a complex, multi-step process involving mineral extraction, refining, active component manufacturing (electrodes and electrolytes), cell manufacturing, and assembly. Cost-effective scaling of these value chains requires significant technical expertise and efficient production processes. Furthermore, there could be significant gestation periods necessary for building new capacity, which can result in supply–demand mismatches. Figure ES2 shows the timelines to bring online different stages of a lithium-ion battery (LIB) production supply chain. Lastly, the current mineral processing and battery production have significant emissions – new ACC battery supply chains must have a low energy footprint and circular processes.

Several of the available batteries use minerals that have limited reserves (for instance, platinum) or are concentrated in a few geographies (such as cobalt). Future ACC batteries should be designed using abundant minerals that can be mined and refined using environmentally sustainable processes.

Figure ES 1 Types of energy storage technologies

Source: Authors’ analysis

Figure ES 2 Timelines for the different stages of the lithium-ion battery production supply chain

Source: Authors’ recreation from IEA (2022c)

We have categorised the most significant technological gaps across five indicators and developed associated metrics to assess and track the progress of ACC batteries (Figure ES3):

Figure ES 3 Indicators for tracking the progress of ACC batteries

Source: Authors’ analysis

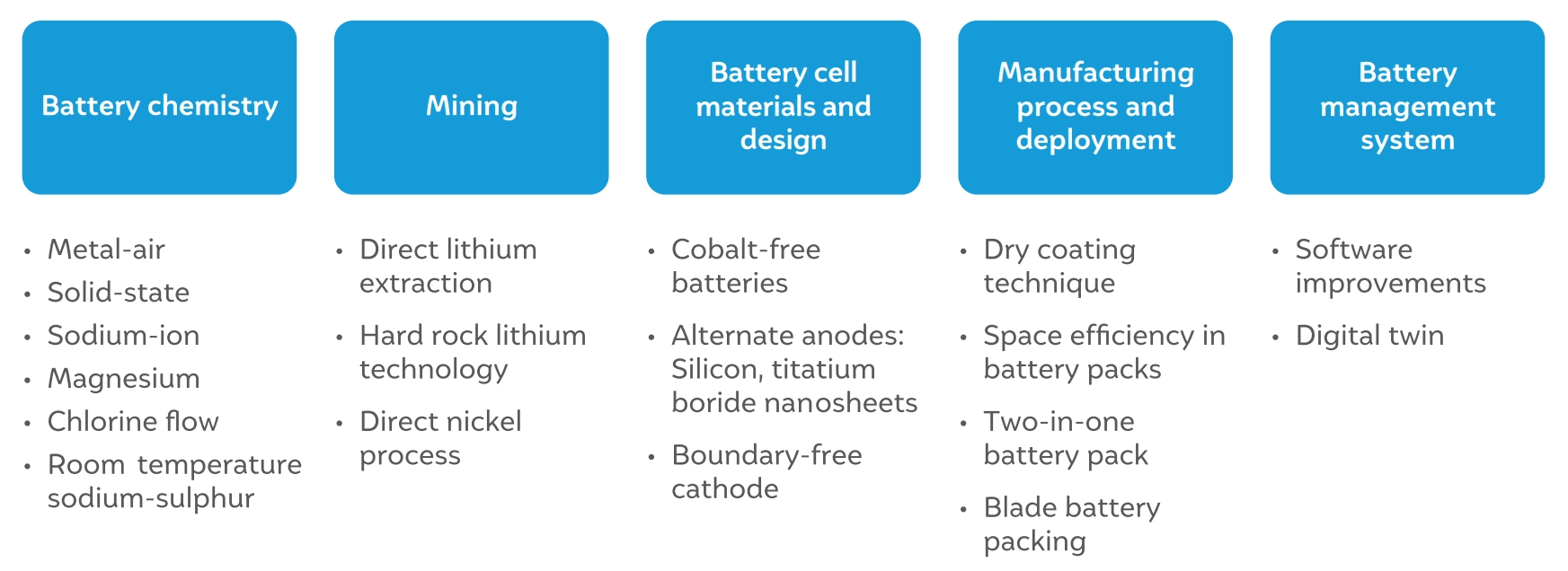

Figure ES 4 Innovations in the battery supply chains for ACC batteries

Source: Authors’ analysis

Several innovations in processes across the value chain – mineral processing, designing, manufacturing, packing, and deployment – enable the development of new ACC batteries (Figure ES4). Majority of the listed innovations improve performance first, followed by scalability and cost. Circularity is still a novel indicator that only a few innovations are achieving. G20 countries should come together to support these innovations and draw them from the margins to the mainstream.

Innovative ACC batteries are at various stages of deployment. We have identified two priority areas and action points for the G20 countries to address and scale up ACC batteries:

Priority 1: Promote innovation and support technological co-development by leveraging the benefits of collective effort

Priority 2: Develop markets and unlock new avenues of deployment by sharing best practices and increasing the flow of finance

Addressing Vulnerabilities in the Supply Chain of Critical Minerals

How Can India Indigenise Lithium-Ion Battery Manufacturing?

Building Resilient Mineral Supply Chains for Energy Security

Solar Geoengineering and the Montreal Protocol